The fence for a summer cottage or village should fulfill two mandatory functions: serve as a protective barrier and be an element of decor. Choosing the right material for its construction, you can emphasize the advantages of the cottage and create a truly reliable and durable protection. It is not surprising that summer residents are increasingly choosing a fence from a metal picket fence - it fully complies with the requirements.

The advantages of this design

Thanks to the modern production of composite elements, summer cottages have transformed: from clumsy rickety fences with rusted pillars, they have turned into beautiful, aesthetically designed fences.

Components - shtaketin and crossbeams - are treated with a polymer composition, tinted in different colors. This is very convenient for creating color harmony with the cottage - the shade of the fence can be matched to the color of the roof tiles, siding or brick.

Metal - the material is strong and wear-resistant, so the metal fence will last much longer than wooden products. The manufacturer gives a guaranteed service life of the constructed fence - up to 30 years. The guarantee extends to color coating - up to 10 years, so in the coming years you can not think about either painting or repair.

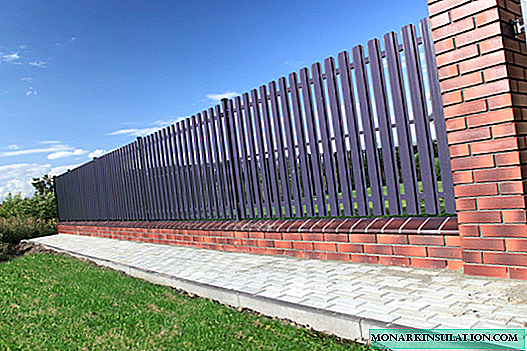

Despite the affordable cost of the material, the fence made of metal picket fence looks flawless, especially in the combined version with brick supports

A large selection of color solutions allows you to build a fence based on the design of the entire suburban area: light colors make the fence almost invisible, bright - focus on it

One of the main advantages of metal parts in their low price. The average price of shtaketin 170-180 cm high is 50 rubles. If you calculate the cost per linear meter of the finished fence, you get a quite acceptable amount - about 300 rubles. It is much cheaper than a similar section of a stone or brick fence. Wooden fences are not very expensive, but they require constant attention: serious processing with special tools, painting, frequent repairs.

The fence is attached to the logs in a hidden or open way, respectively, for fixing some options decorative metal rivets are necessary

Features of load-bearing and enclosing products

The bearing part of the country metal fence is made up of pillars, and the fence is made of steel picket fence. For the manufacture of poles, various materials are used, so often the fences are combined: the metal picket goes well with brick, concrete and even wood. But metal supports are also in demand - usually a pipe with a diameter of 60 mm and above. It must be remembered that the elements of the fence are heavier than simple wooden slats or netting, so the pillars must be powerful and reliably dug.

Self-erected brick supports, the cost of which is much higher than a metal fence, can be replaced with a budget option - rolling poles manufactured at the factory

The distances between the supports are filled with a metal fence fixed on the crossbars of a profiled pipe, the dimensions of which are 20x40 mm. Sometimes a larger cross section is used, but usually this is enough.

Metal pipes painted in the color of the picket fence are the most inexpensive supports, and they are quick and easy to install

The picket itself is a profile element of a certain length, made of galvanized steel by the method of rolling and coated on top with a polymer decorative coating. The polymer is a bright or more neutral color: red, brick, blue, gray, green. The thickness of the galvanized sheets is half a millimeter.

Metal picket is different in profile shape and the number of bends. This view has a V-shaped, slightly rounded shape

There are several profile options. By changing the length, width, bends and design of the upper part, manufacturers have achieved various styles of color. Here are three options for a metal fence that look completely different.

The “Classic” variant is distinguished by the rounded ends of the shtaketin and their dense arrangement - two rows of elements on both sides make the fence solid

The airiness of the Gothic fence provides the pointed shape and arrangement of the shtaketins: they are mounted on both sides in a checkerboard pattern, but with small intervals

The Neptune variant differs from Gothic only in the form of the elements - the upper ends of the shtaketin are cut into three parts and resemble a trident

The picket is "gaining" quickly, performing the same type of movement. The focus is on the accuracy of the layout and the strength of the fasteners.

If you look at a fence made of metal picket fence from different angles, it changes its appearance: from solid to transparent

Self-Fence Installation Technology

It would seem that such an even and beautiful fence cannot be built on its own. In fact, everything is simple. Installation of the fence consists in a clear layout, installation of support posts with jumpers and assembly of the main part.

Preparation of materials, tools and construction site

First you need to familiarize yourself with the assortment of picket fence in the store and choose the right one. In order not to purchase excess goods, you should carefully measure the perimeter of the enclosed area, and then, based on the calculations, buy the required number of profiles and pipes. You can take unprocessed galvanized steel, but then you will have to purchase a primer and paint separately, and then spend time processing. It will be a little cheaper, but longer in time, and the decorative layer will not lie as professionally as in the factory.

Armed with a tape measure, it is necessary to distribute the shtaketin between the supports as accurately as possible - the aesthetic component of the fence depends on this

There will be two bars - above and below, so when calculating the length of the perimeter must be multiplied by two. The choice of lags is large, their length is 2-12 m. We buy crossbars, taking into account the optimal distance between the posts - from 2.5 m to 4. Large intervals are impractical - there will be too much load on the logs, and they can sag. The calculation is easy: for 25 meters of fencing, 10 pillars will be required, the same number of 5-meter crossbars (or twenty if they are twice as short - 2.5 meters each).

The distance from the shtaketin to the ground protects the fence elements from rapid wear. However, it should not be so large that people or animals easily entered the site

The standard width of the shtaketin is 100 mm or 120 mm. Their number depends on the "transparency" of the fence. The longer the mounting interval, the airier the fence will be. There are also deaf options when the fence is fixed butt or lap, but on both sides. To create a "transparent" fence, 5 products per 1 m are enough - the distance between the shtaketins will be equal to their width.

The fasteners used to fix the elements of the fence - self-tapping screws or special bolts with washers that prevent the rapid wear of the polymer coating and extend its life without repair. Sometimes they use special fasteners for the fence, also made of profile.

For fastening the steel profile to the crossbars, galvanized fasteners are excellent - it is as durable as the fence elements

The tool is better prepared in advance. For earthwork, a shovel or drill is needed, for fixing parts - a screwdriver. You may also need a welding machine - this depends on the design of the fence itself, as well as the gate and gate. The cord and laser level will help to accurately distribute the elements.

The construction site should be cleaned of debris and grass, leveled. The perimeter is marked with pegs between which the cord is pulled. Designate the exact location of the pillars and get to work.

An interesting effect is obtained when using double coloring: the fence is bright on the outside, and on the inside - light, not conspicuous

Mounting support poles

We tear out the pits, the depth of which should be at least 50 cm. For a more reliable fastening of the column in the ground, it is not enough just to fill the hole with soil or sand, concreting is necessary. We prepare the solution according to the standard scheme, while you can buy the finished mixture or make your own - from cement and sand. Each pillar should be strictly vertical, so it is best to use the construction level as often as possible. The distance between the posts is measured taking into account the length of the crossbars. The installed support must be fixed for a while - until the concrete has completely dried (at least two days). For this, wooden supports are usually used.

Concreting of metal supports is an obligatory stage in the construction of the fence. The durability and reliability of the fence depends on the quality of the installation of poles

Related article: Installing fence posts: mounting methods for various structures

Metal structure assembly

We mark the places of fastening of the crossbars and, using self-tapping screws, we mount them around the entire perimeter, and at the same time we check the accuracy of the marking. Then we arm ourselves with a marker and sequentially along the entire length we designate the fixation points of the picket fence. At this stage, patience, attention and accuracy will be required.

Given the standard width of the shtaketin, we determine the interval between the elements of the fence. The wider the distance between the profiles - the “easier” the fence

The fence will look perfect in the only case - if the distance between the shtaketin is the same. The simplest thing remains - to fasten the shtaketin with a screwdriver. A beautiful and reliable fence is ready, you can do the installation of gates and gates.

A solid fence made of metal picket fence is an excellent option for fencing for a summer cottage. It compares favorably with the wooden counterparts in the neighborhood.

Sometimes a horizontal bar is used as horizontal bars. It is not as durable as polymer-coated steel, so it requires additional antiseptic treatment and painting. Of course, the distance between the supports should be small - it is more difficult for a tree to support the weight of a metal fence.

Smart installation video example

As they say, it’s better to see it with your own eyes once and everything will become clear at once!